UNIVERTOR AC Series

Left and right machine variants available

Linear guides designed with high accuracy and preload classes in all machine axes

Direct path measuring systems in all machining axes (glass scales)

VERSION WITH ONE SPINDLE UNIVERTOR AC-1

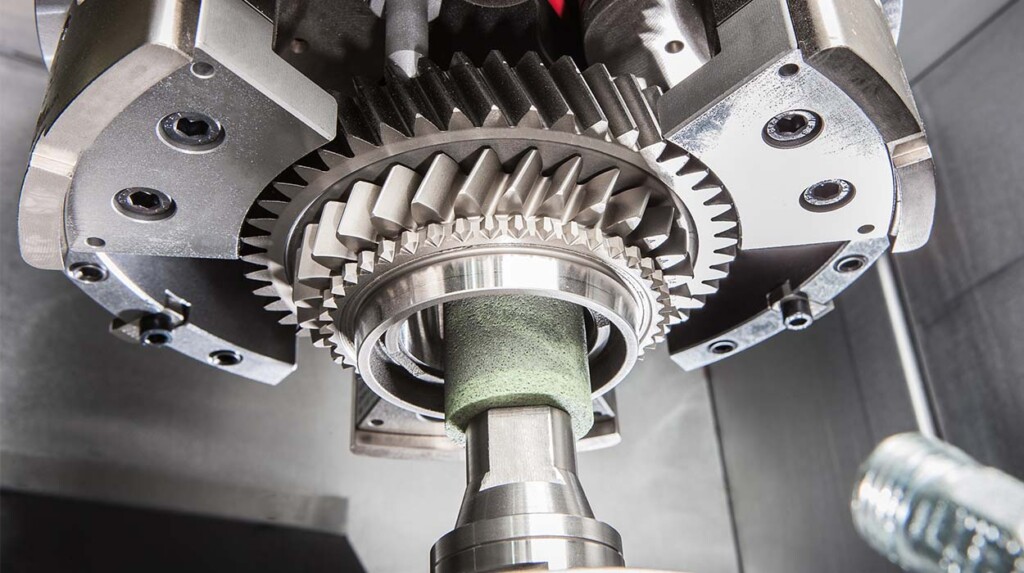

The machines of the AC-1 series are highly flexible and predestined for the complete machining of different batch sizes, with very high quality requirements. The design as a right-hand or left-hand machine concept realizes the ideal adaptation to the production sequence. Highly productive simultaneous machining in one machine with up to two powerful disk turrets (4 axes) or several grinding spindles enables intelligent technology processes with high savings potentials and creates high-precision machining results.

CONCEPTIONAL ADVANTAGES UNIVERTOR AC-1

- Left and right machine variants available

- Machine columns with very good stiffness behavior and optimized damping properties due to remaining sand in the model

- Linear guides designed in high accuracy and preload classes in all machine axes

- All linear guides and feed drives arranged outside the working area for protection against chips

- Direct path measuring systems in all machining axes (glass scales))

- High dynamics of all machine axes

- Optimal chip fall downwards

- Self-built turning spindles with very good concentricity and axial run-out accuracy values

- Easy installation and removal of the turning spindle in the event of repairs

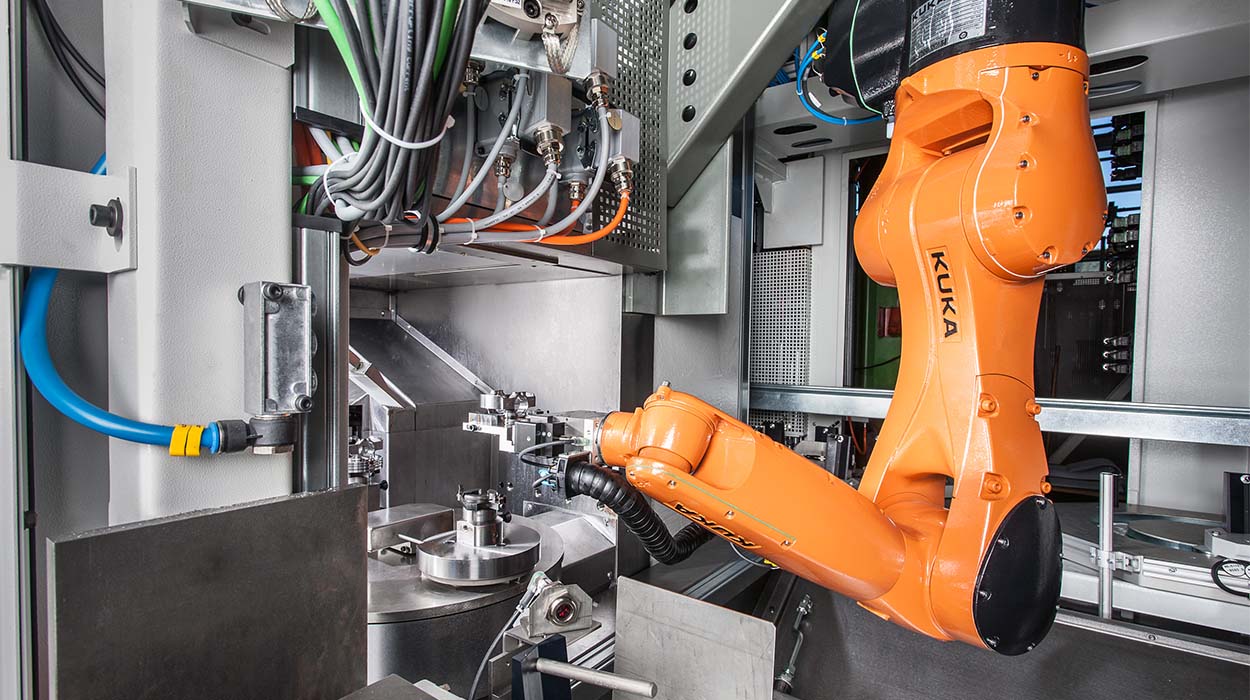

- Compact footprint due to integrated handling unit (2-axis version with swivel unit)

- Main spindle A6 according to DIN 55026

- Interface in tool turret VDI or Capto possible

OPTIONS UNIVERTOR AC-1

- Integrated measuring probe possible

- Driven tools possible (for drilling operations)

- 4-axis machining possible (by additional turret on cross slide unit)

- Additional internal grinding unit possible

- Additional external grinding unit possible

- Combination of turning and grinding in smallest space possible

- Additional drilling head possible

- Additional Y-A axis unit with milling spindle for gear milling possible

- Spatial separation of both machine halves possible (to a certain extent independent of each other)

- Simultaneous or progressive machining possible

(with possibility of turning the workpieces) - Various automation variants possible

VERSION WITH TWO SPINDLES UNIVERTOR AC-2

With the two-spindle UNIVERTOR AC-2, simultaneous machining of two workpieces or machining of one workpiece in two clampings is possible. It has the same modularity and flexibility as the UNIVERTOR AC-1. The possibility of technology integrations of innovative processes such as rotation turning, hard turning, grinding, drilling or milling results in a significant reduction of in-house logistics processes and creates high-precision machining results.

CONCEPTIONAL ADVANTAGES UNIVERTOR AC-2

- Left and right machine variants available

- Machine columns with very good stiffness behavior and optimized damping properties due to remaining sand in the model

- Linear guides designed in high accuracy and preload classes in all machine axes

- All linear guides and feed drives arranged outside the working area for protection against chips

- Direct path measuring systems in all machining axes (glass scales))

- High dynamics of all machine axes

- Optimal chip fall downwards

- Self-built turning spindles with very good concentricity and axial run-out accuracy values

- Easy installation and removal of the turning spindle in the event of repairs

- Compact footprint due to integrated handling unit (2-axis version with swivel unit)

- Main spindle A6 according to DIN 55026

- Interface in tool turret VDI or Capto possible

OPTIONS UNIVERTOR AC-2

- Integrated measuring probe possible

- Driven tools possible (for drilling operations)

- 4-axis machining possible (by additional turret on cross slide unit)

- Additional internal grinding unit possible

- Additional external grinding unit possible

- Combination of turning and grinding in smallest space possible

- Additional drilling head possible

- Additional Y-A axis unit with milling spindle for gear milling possible

- Spatial separation of both machine halves possible (to a certain extent independent of each other)

- Simultaneous or progressive machining possible

(with possibility of turning the workpieces) - Various automation variants possible

TECHNICAL DATA

AC

Max. turning diameter

150 mm

Max. chuck diameter

215 mm

Max. Feed force X/Z (40 % CDF)

8 / 10 kN

Working stroke X/Z-axis

830/180 mm

Max. Process speed X/Z

60/30 m/min

Ball screw diameter X1/Z1

40/40 mm

Number of tools

12

Tool holder

VDI40 / Capto

Tool flight circle

670 mm

Main spindle

AC

Spindle bearing diameter

90 mm

Spindle flange

A6

Drive power 100 % CDF

16,8 (20,9) kW

Drive power 40 % CDF

21,5 (26,8) kW

Rated speed

1600 rpm,

Max. Speed

4500 U/min, rpm,

Torque 100 % CDF

100 (200) Nm

Torque 40 % CDF

128 (255) Nm

PRODUCT COMPETENCE

Anfrage/Request

Ich interessiere mich für eine Fertiglösung von WEISSER/I am interested in a ready-to-use solution from WEISSER