UNIVERTOR AM Series

Highly ribbed monobloc machine base

Long travels despite compact external machine dimensions

Precision linear guide ways in horizontal and vertical direction

VERSION WITH ONE OR TWO SPINDLES

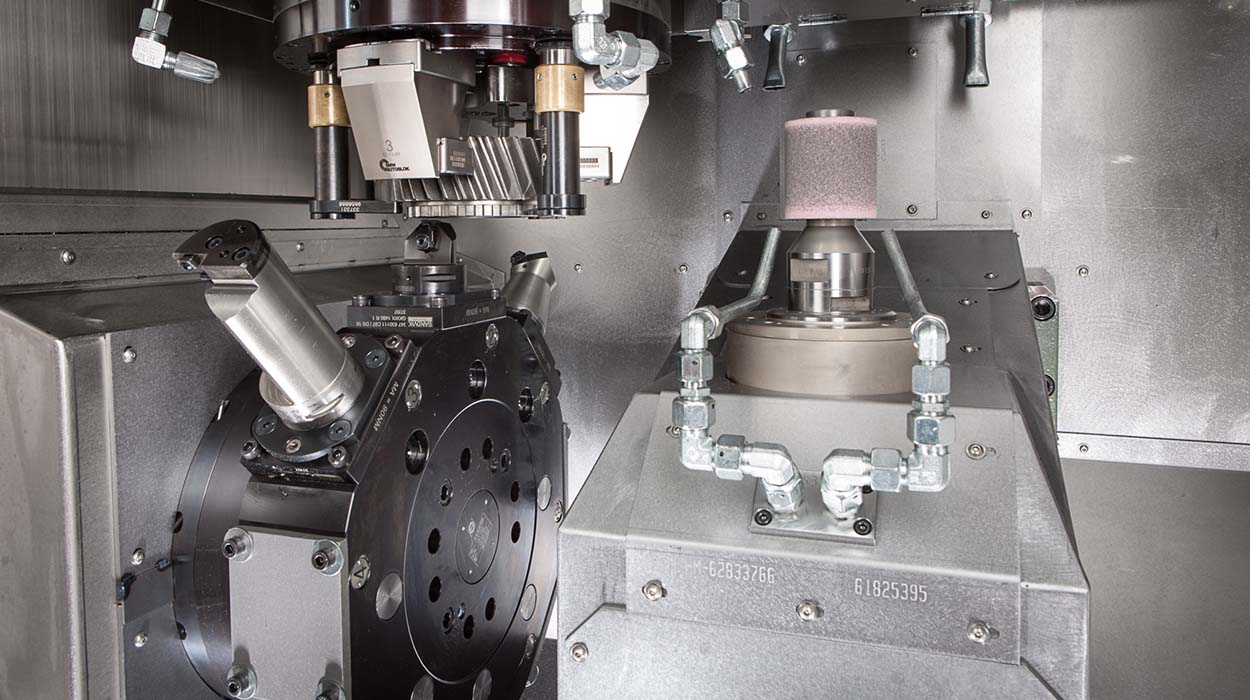

The modularly designed vertical precision turning machines of the UNIVERTOR AM are highly flexible and predestined for the complete machining of different batch sizes at lowest costs per piece. Technology integrations of rotation turning, hard turning, grinding, drilling, milling in one workspace enable high workpiece quality, contour accuracy and surface finish. In addition, setup, programming and idle times are significantly reduced. Highly productive simultaneous machining in one machine with up to two powerful disc turrets realize intelligent technology processes.

CONCEPTIONAL ADVANTAGES UNIVERTOR AM-1 / AM-2

- Left and right machine variants available

- Machine base with very good stiffness behavior

and optimized damping properties due to remaining sand in the model - Linear guides designed in high accuracy and preload classes in all machine axes

- All linear guides and feed drives arranged outside the working area for protection against chips

- Direct path measuring systems in all machining axes

(glass scales) - High dynamics of all machine axes

- Optimal chip fall downwards

- Self-built turning spindles with very good concentricity and axial run-out accuracy values

- easy installation and removal of the turning spindle in the event of repairs

- Main spindle A8 or A11 according to DIN 55026 possible

- Interface in tool turret VDI or Capto possible

OPTIONS UNIVERTOR AM-1 / AM-2

- Integrated measuring probe possible

- Driven tools possible (for drilling operations)

- 4-axis machining possible ( through additional turret on cross-slide unit)

- Additional internal grinding unit possible

- Additional external grinding unit possible

- Combination of turning and grinding in smallest space possible

- Additional drilling head possible

- Additional Y-A axis unit with milling spindle for gear milling possible.

- AM-2: Simultaneous or sequential machining possible (with possibility of turning the workpieces)

- AM-2: Various automation variants possible

VERSION AM-T

In the working area of the UNIVERTOR AM-T with vertical spindle-slide arrangement and multifunction slide, the workpieces are cycled through the machine according to the transfer principle. The transfer takes place directly from the hanging pick-up spindle into the standing vertical spindle. The additional turrets, drilling heads or multifunctional slides mounted on the special column module enable a wide range of machining options. In this way, subsequent operations can be carried out in one work area with significantly reduced non-productive times and with maximum transfer precision between the clamping units. This guarantees highly accurate form and position tolerances on the workpieces.

CONCEPTIONAL ADVANTAGES UNIVERTOR AM-T

- Two-spindle design with pick-up spindle and vertically positioned counter spindle

- Workpiece passage from left to right or vice versa possible

- Machine column with very good stiffness behavior and optimized damping properties due to remaining sand in the model

- Linear guides designed in high accuracy and preload classes in all machine axes

- All linear guides and feed drives arranged outside the working area for protection against chips

- Direct path measuring systems in all machining axes (glass scales)

- High dynamics of all machine axes

- Optimal chip fall downwards

- Self-built turning spindles with very good concentricity and axial runout accuracy values

OPTIONS UNIVERTOR AM-T

- Integrated measuring probe possible

- Driven tools possible (for drilling operations)

- Additional drilling head possible

- NC lift-off tool holder possible

Technical data

AM

AM-T

Max. turning diameter

360 mm

450 mm

Max. chuck diameter

410 mm

500 mm

Max. Feed force X/Z (40 % CDF)

8 / 10 kN

8 / 10 kN

Working stroke X/Z-axis

1.400 / 440 mm

1.400 / 350 mm

Max. Process speed X/Z

60/30 m/min

60/30 m/min

Ball screw diameter X1/Z1

40/40 mm

40/40 mm

Number of tools

12

8 / 12

Tool holder

VDI40 / 50 / Capto

VDI40 / 50 / Capto

Tool flight circle

740 mm

Main spindle

AM

AM-T

Spindle bearing diameter

120 mm

120 mm

Spindle flange

A8

A8

Drive power 100 % CDF

35,1 kW

35 kW

Drive power 40 % CDF

40 kW

40 kW

Rated speed

780 rpm

780 rpm

Max. Speed

3500 rpm

3500 rpm

Torque 100 % CDF

430 Nm

430 Nm

Torque 40 % CDF

610 Nm

610 Nm

Product competence

Anfrage/Request

Ich interessiere mich für eine Fertiglösung von WEISSER/I am interested in a ready-to-use solution from WEISSER