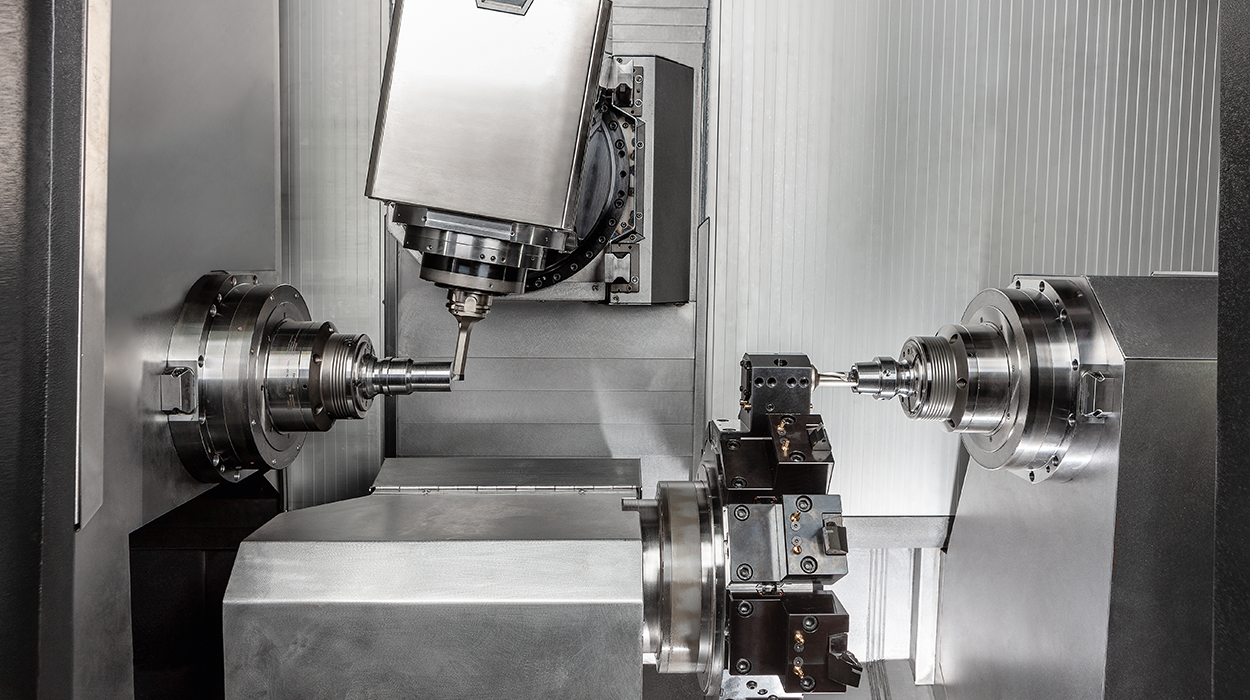

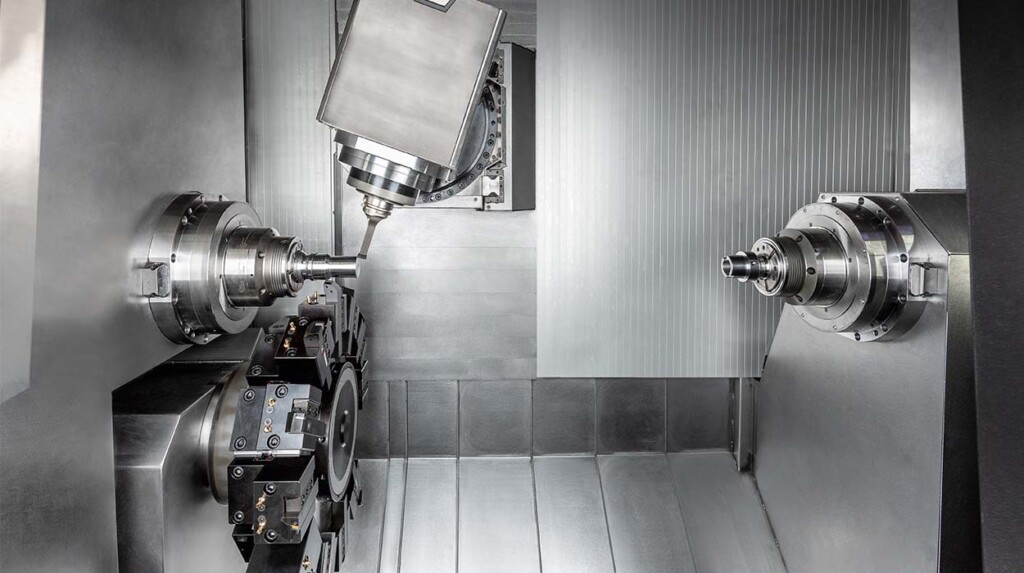

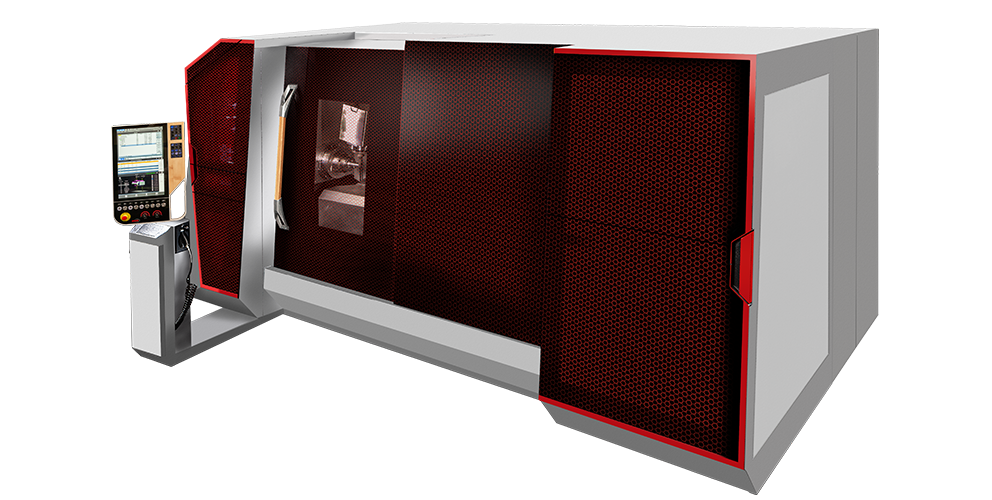

Available as a highly efficient 5-axis precision turning machine as well as a mill-turn center for autonomous, very precise and cost-effective 6-sided complete machining. The high flexibility of the ARTERY enables its use in many industrial sectors, e.g. precision technology, aerospace, mechanical engineering, medical technology, and many others. The high-quality ARTERY manufactures first-class surfaces as well as maximum precision and process reliability and features high vibration damping and flexibility.

ARTERY

Simultaneous turning and/or turning and milling

Large working area with compact footprint

Vibration optimized construction

MULTIFUNCTIONAL HIGH-PERFORMANCE PRECISION CENTER FOR TURNING OR TURN-MILL COMPLETE MACHINING

CONCEPTIONAL ADVANTAGES ARTERY

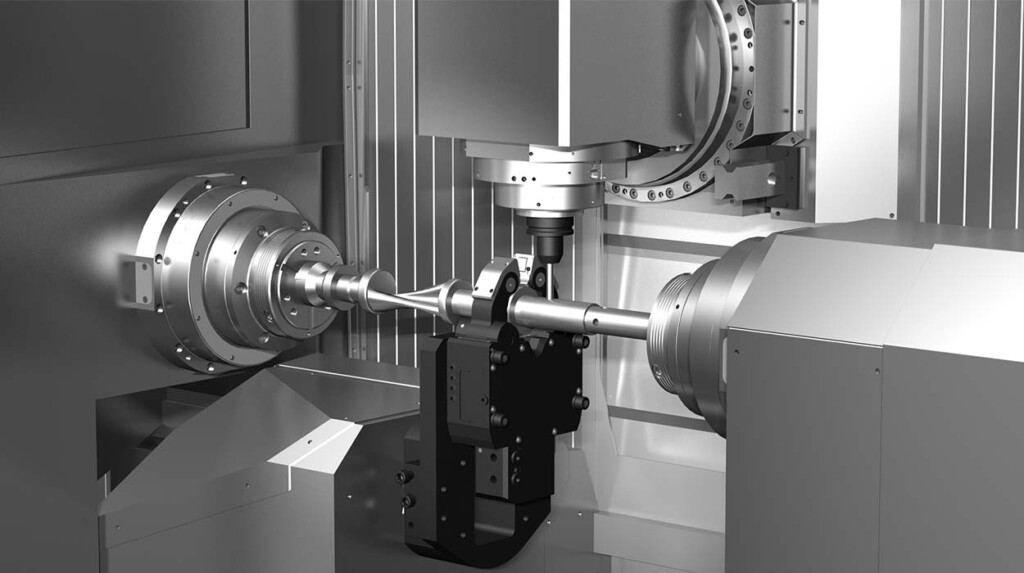

- Parallel turning or turning and milling

- User-friendly, functional design

- Large working area with compact footprint

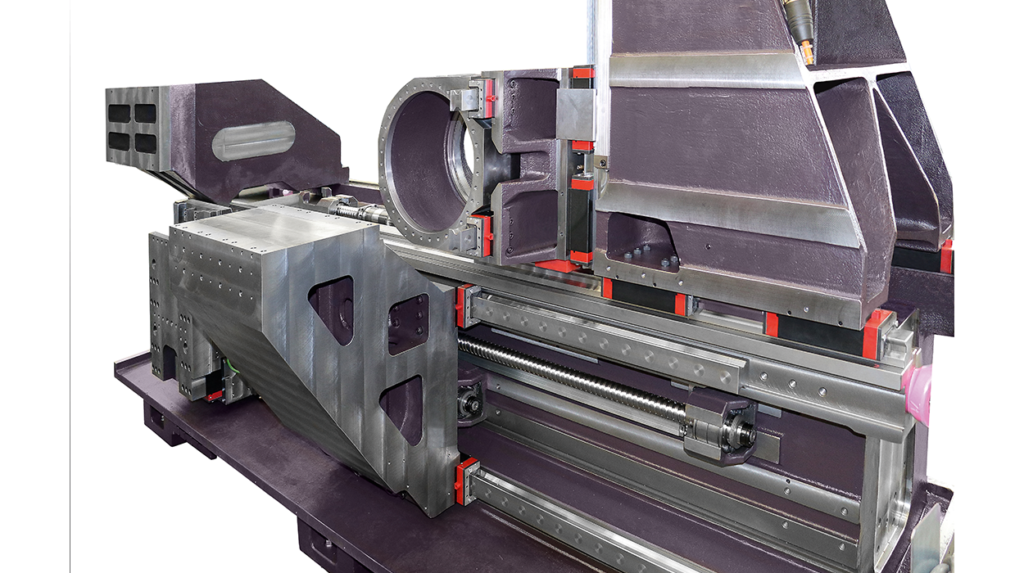

- Vibration-optimized design

- Service-friendly access to all relevant components

- Generously equipped, swiveling control panel

- Vibration damping cast construction

- Long Z-axis for 1,200 mm machining length

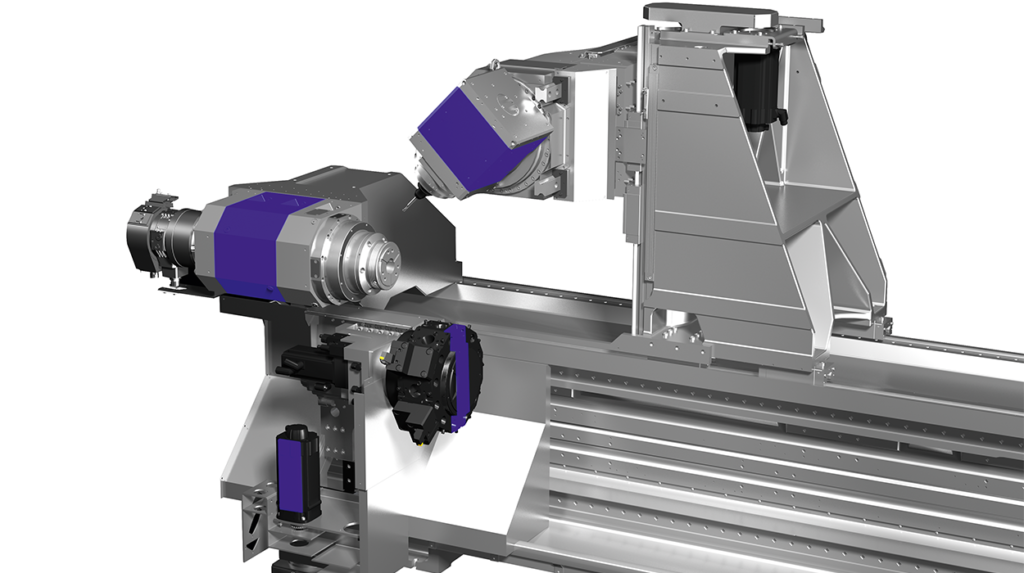

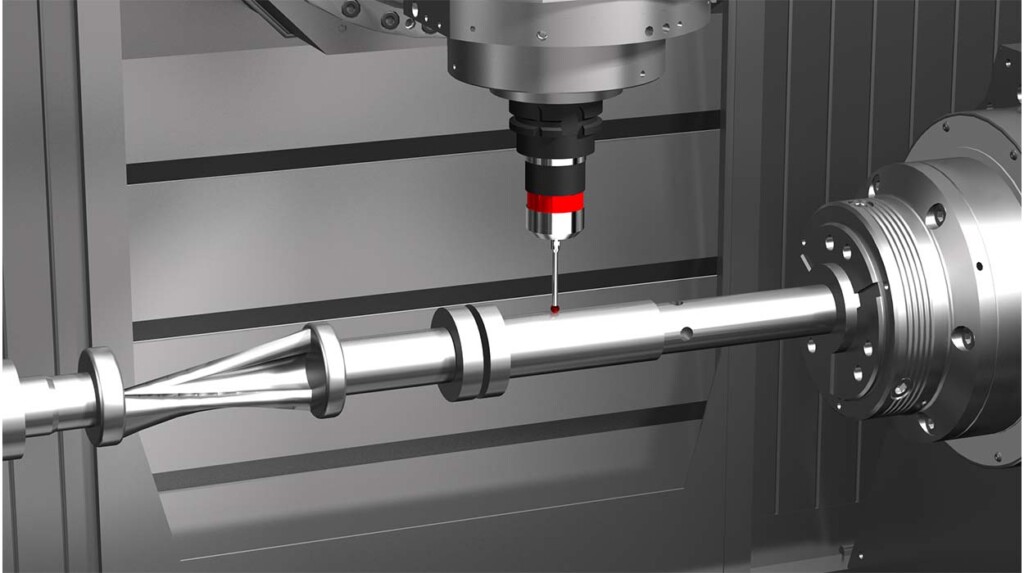

- Y-axis (+130/-80 mm) with B-axis and milling spindle (HSK-T 63)

- Compact cartridge milling spindle (B-axis)

- Milling spindle with max. 20,000 min-1, power up to 20 kW, 100 Nm

- 38/102-cartridge chain magazine High-speed tool changer

- Complete machining from bars

- High stability and precision in machining of workpieces

- Identical main and counter spindle

TECHNICAL DATA

M-1 4X

M-2 5X

Product competence

Anfrage/Request

Ich interessiere mich für eine Fertiglösung von WEISSER/I am interested in a ready-to-use solution from WEISSER