UNIVERTOR AE Series

Automatic loading with the integrated pick-up system

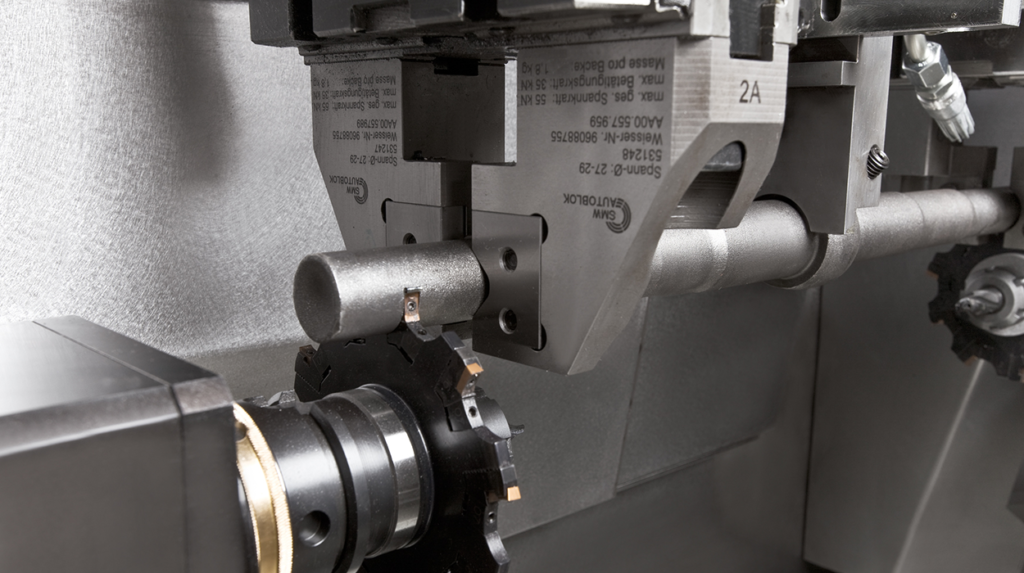

Powerful centric clamping for the reliable fixing of raw parts

Centering, spindling, drilling and milling of shaft ends

UNIVERTOR AE

Modular designed finishing machine with WEISSER Pick-up system for parallel machining of one workpiece. The movable base carrier is equipped with robust centric clamps for the pick-up of shaft-shaped workpieces. No additional robots or gantry solutions are necessary, because the machine loads itself. Economical cutting to length and centering on the UNIVERTOR AE ensures precise workpiece pick-up for subsequent process steps within the complete machining operation. The design with robust disc or crown turrets enables spindling, milling, drilling and deep boring of the shaft ends using driven tools.

CONCEPTIONAL ADVANTAGES UNIVERTOR AE

- Left and right machine versions available

- End machining of shaft-shaped components (milling, sawing, centering, drilling)

- Easy automation, only pallet belt required

- Patented pick-up principle adapted to use for end machining of shafts

- Machine column with very good stiffness behavior and optimized damping properties due to remaining sand in the model

- Linear guides designed in high accuracy and preload classes in all machine axes

- Direct path measuring systems possible in all machining axes (glass scales)

- High dynamics of all machining axes

- Optimal chip fall downwards

OPTIONS UNIVERTOR AE

- Two HSK 63/80 machining spindles per machining side

- 6-station crown turret HSK 63 per machining side

- 8-station HSK 63/80 disc turret per machining side

- 12-station HSK 63 disc turret per machining side

- Center drive spindle possible instead of rigid centric clamping

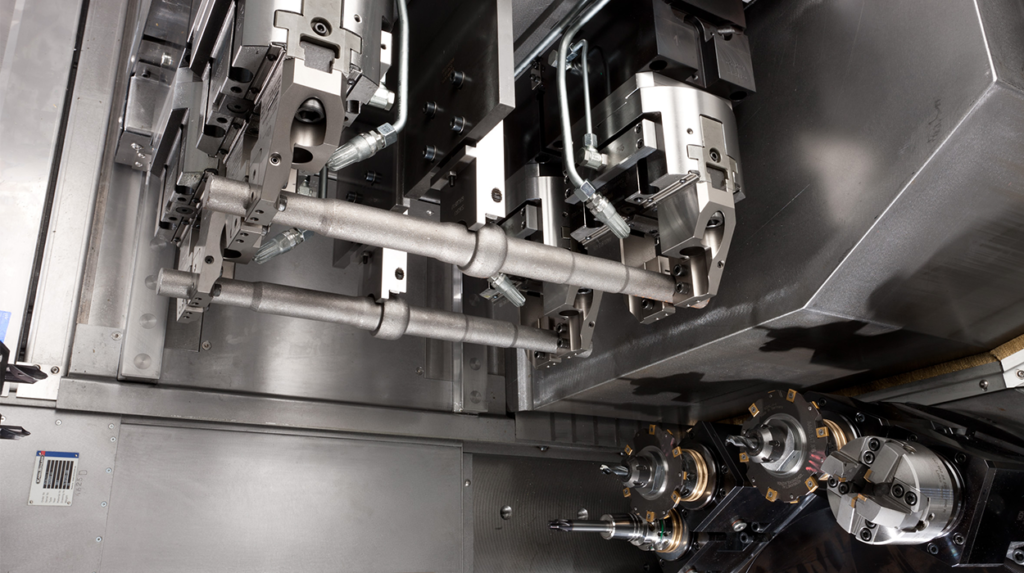

UNIVERTOR AE-T

Modular designed finishing machine with WEISSER Pick-Up System for parallel machining of two workpieces as twin version. The concept of a fixed and a movable disc or crown turret, in combination with the movable mounting slide of the centric clamping device, enables simultaneous machining on both shaft ends. No additional robots or gantry solutions are necessary, because the machine loads itself.

CONCEPTIONAL ADVANTAGES UNIVERTOR AE-T

- End machining of shaft-shaped components (milling, sawing, centering, drilling)

- Synchronous machining of two workpieces, for optimization of piece costs

- Simple automation, only pallet belt required

- Patented pick-up principle adapted for end machining of shafts

- Machine column with very good stiffness behavior and optimized damping properties due to remaining sand in the model

- Linear guides designed in high accuracy and preload classes in all machine axes

- Direct path measuring systems possible in all machining axes (glass scales)

- High dynamics of all machine axes

- Optimal chip fall downwards

Technical data

AE

Max. workpiece diameter

150 mm

Max. workpiece lenght

600 mm

Max. Feed force X/Z (40 % CDF)

5 / 5 kN

Max. Feed force X2 (40 % CDF)

12 kN

Working stroke X/Z-axis

350 / 1.900 mm

Working stroke Z2-axis

457 mm

AE

Max. Process speed X/Z

30 / 50 m/min

Max. Process speed Z2

30 m/min

Ball screw diameter X/Z

40 / 40 mm

Ball screw diameter Z2

40 mm

Number of tools

AE: 2 / 6 / 8 (2x) / AE-T: 2 x 6 (2x)

Tool holder

HSK63

Product competence

Anfrage/Request

Ich interessiere mich für eine Fertiglösung von WEISSER/I am interested in a ready-to-use solution from WEISSER