MULTICENTER

Small depth of engagement and easy setting-up

Big field of tool application

Vibration optimized construction

Versatile machining possibilities for precision and flexibility

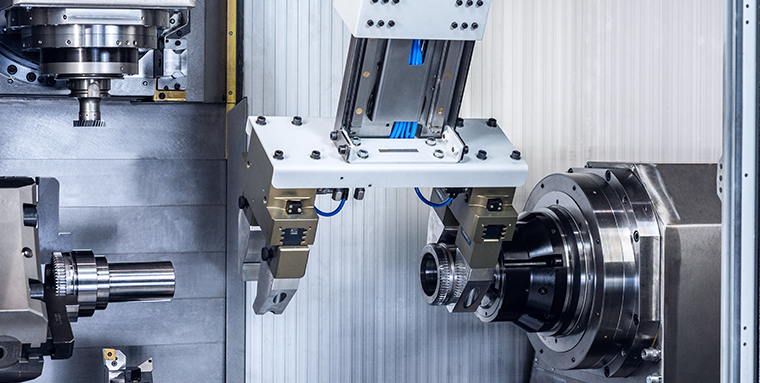

The MultiCenter presents itself as multifunctional machining center with different options. Beside the option as pure turning machine it can also be configured as turning-milling center. Due to its remarkable flexibility the MultiCenter is used in different industrial sectors. Amongst others in precision technology, aerospace, mechanical engineering, medical engineering and many other industrial sectors.

The basic machine of the MultiCenter impresses with a horizontal spindle arrangement and a compact design. The machine column made of high-quality grey cast iron, strongly ribbed and with extraordinary stiffness, offers optimum damping characteristics. The design of the working area walls guarantees an efficient removal of chips. The spacious working area door enables a simple scaffolding and resetting, as well as quick changes of chucks and tools.

CONCEPTIONAL ADVANTAGES MultiCenter

- Small depth of engagement and easy setting-up: With a depth of engagement of only 455 mm between machine front and spindle axis the setting-up is simplified.

- Big field of tool application: the MultiCenter is designed for big tools up to max. 330 mm.

- Efficient automation: The seamless integration of loading-and unloading handling in the machine area is optional and creates a high degree of automation at low cost.

- Ergonomic operation: The optional swivel-type operator panel which is height-adjustable up to 240 mm offers a comfortable and ergonomic operation.

- Customizable chip removal: The flexible option of the chip conveyor arrangement (right or left) optimizes the space requirement and the work environment.

- Easy maintenance: The chip conveyor can be pulled laterally and from the front, this facilitates maintenance and cleaning and reduces downtimes.

Technical data

Turning length

1.200 mm

Chuck diameter

up to 350 mm

Max. Feed force W/X/Y/Z (25 % CDF)

7,5 / 7,5 / 7,5 / 7,5 kN

Working stroke X (top / bottom)

600 / 200 mm

Working stroke Y-axis

210 (+130 / -80) mm

Working stroke Z-axis (top / bottom)

1.100 / 1.200 mm

Max. Travel speed W/X/Y/Z

45 / 40 / 40 / 45 m/min

Ball screw diameter W/X/Y/Z

40 / 40 / 40 / 40 mm

Spindle bearing diameter

120 (160) mm

Spindle diameter

65 (105) mm

65 (105) mm

65 (105) mm

Spindle bore diameter

80 (120) mm

Drive power 100 % CDF

22 (48) kW

Drive power 40 % CDF

24 (52) kW

Nominal speed

1.400 (780) rpm

Max. Speed

5.700 (3.200) rpm

Torque 40 % CDF

191 (795) Nm

Torque 100 % CDF

150 (585) Nm

Product competence

Anfrage/Request

Ich interessiere mich für eine Fertiglösung von WEISSER/I am interested in a ready-to-use solution from WEISSER