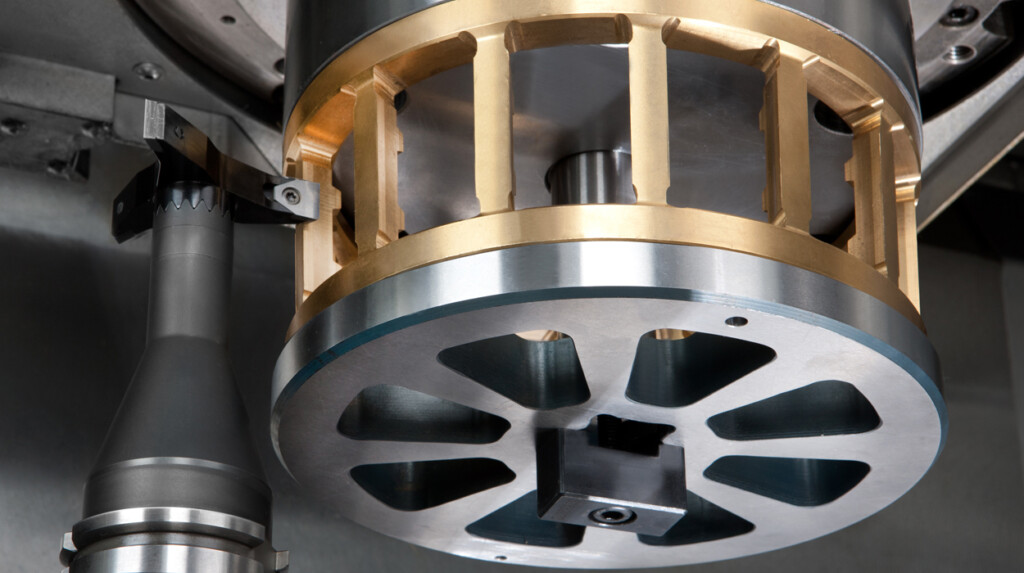

Compared to the milling of bearing cages, which are typically made of brass, shorter cycle times and tribological matched contours with greater precision can be achieved for cylindrical roller bearings.

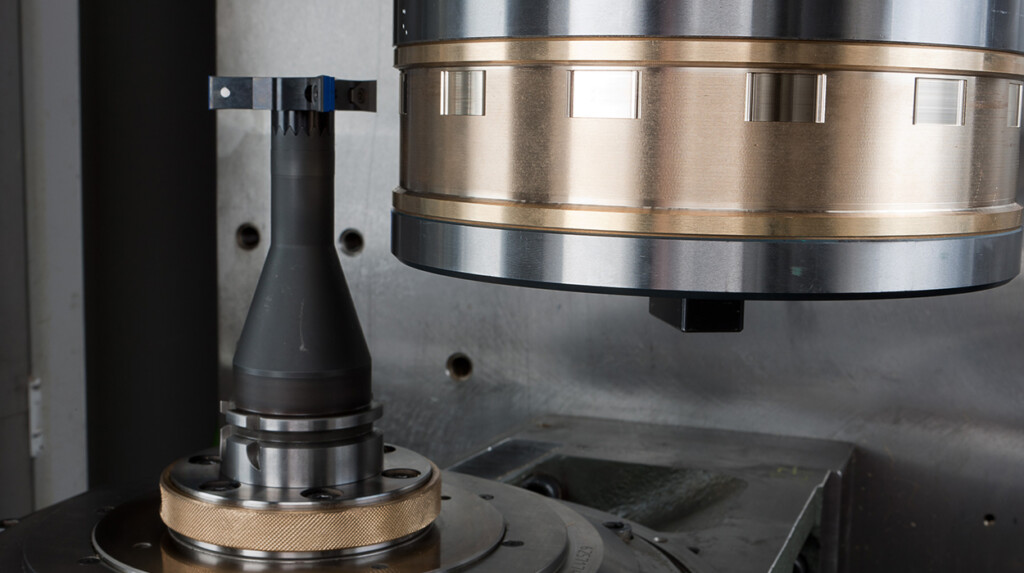

Whirling or impact/turn-milled brass cages are perfect for heavy-duty bearings and therefore are particularly useful in planetary gearboxes, heavy-duty wind-power planetary gears, railway axles and construction equipment, such as cranes or excavators vehicles.

The WEISSER whirling method offers these unique user benefits:

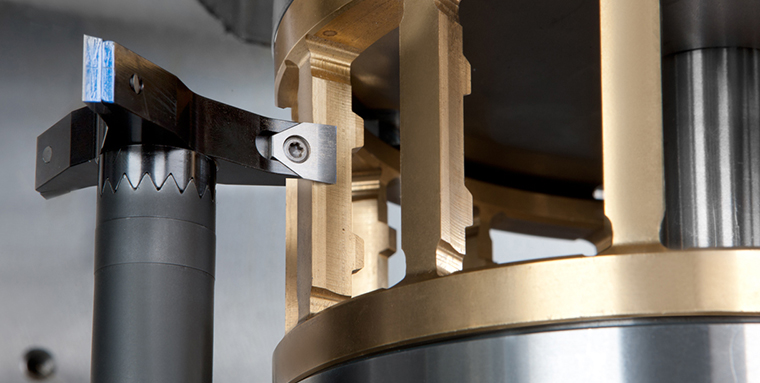

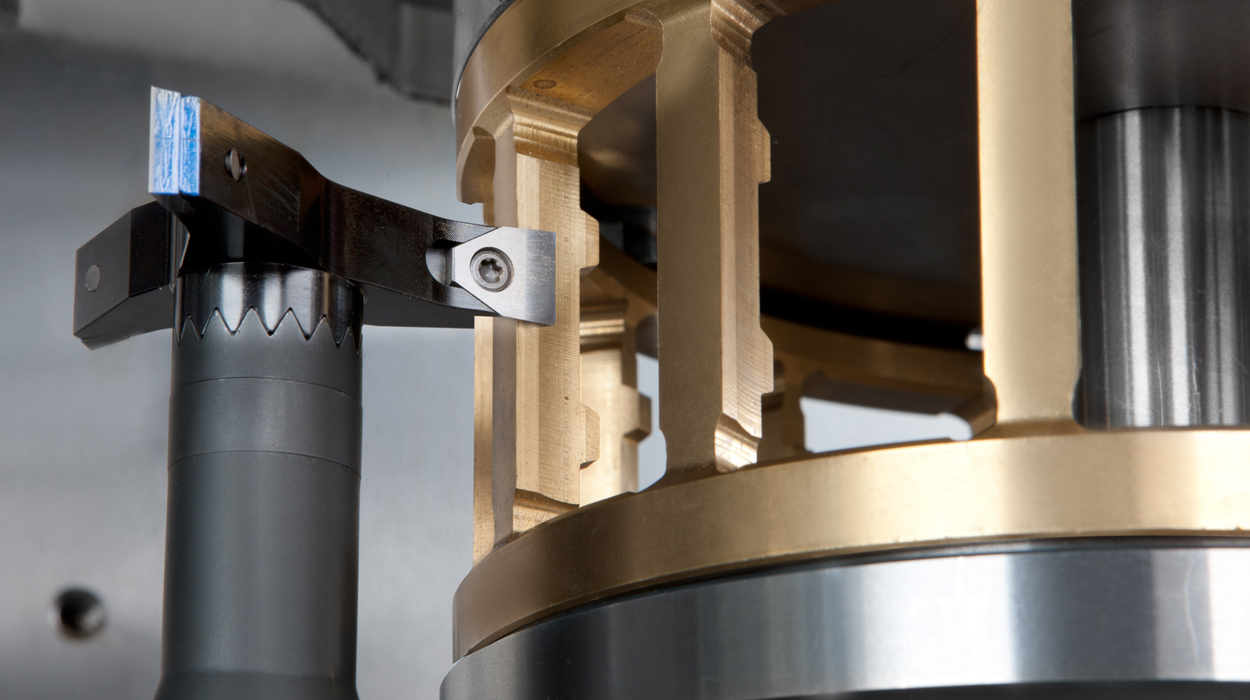

- High efficiency due to the substitution of time-consuming and expensive manufacturing processes, such as milling, drilling and broaching or boring and punching

- Improved contact conditions between roller and cage bar with the new concave pocket-window geometry

- Ideal lubricant film formation in the rolling region with less wear

- Self-retaining function of the rolling elements due to concave ridge forms: Facilitated assembly due to snap-in assembly of the rollers without a separate device or caulking to prevent falling out

The method also allows efficient machining of stable full-mould cage forms so that they can be used instead of sheet-metal cages. This results in

- Greater solidity and durability in spite of a reduced overall mass, thereby reducing inertia forces in operation

- Increase of the static as well as dynamic load rating and service life due to the machining options for solid components